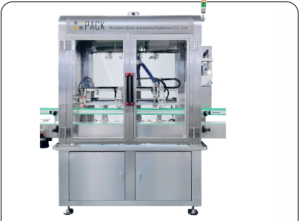

In the noisy world of manufacturing, making the right equipment selection can mean the difference between efficient production or better-quality products. The great accuracy, versatility, and efficiency of the pump filling machine have led to this type of filler being the desired choice for many industries. This will take a deep dive into why a pump filling machine investment may just change the game for your production line.

Precision in Liquid Handling

For a solution to a variety of different liquid viscosities, look no further than our advanced pump filling machines. These machines maintain an accuracy rate that is generally within ±1% of targeted fill volume, whether it be thin, water-like products or thick creams and gels. This level of precision reduces waste, maintains specificity and upholds stringent industry regulations.

Excellent Liquids Compatibility

Among the most shining features of pump fillers lies in their ability to made quite versatile. This makes them perfect for both light and heavy-duty industries such as the food and beverage, pharmaceuticals, chemical sectors. Peristaltic pumps, on the other hand, are best for sterile applications because they help minimize the risk of cross-contamination, while gear pumps are designed to move viscous fluids that do not contain particles.

Enhanced Production Speed

The ability to pack the chemicals in thinner plastic containers are greatly reduced the carbon foot print of the production because of the weight reduction of the containers themselves. You have machines that fill a couple of containers a minute to thousands, depending on the model and the type of liquid being filled. A mutil-head pump filling machine will further boost the throughput for high-volume production lines, handling upwards of 200 containers per minute.

This is flexible with container and volume variance

The versatility of pump fillers is not limited to what they fill, but also the vessels into which they fill the substance. They are also designed to handle different container sizes from small sample bottles up to large industrial containers. What's more, the fill volumes are easy to adjust, usually by a few simple set-up changes on the in-line interface of the machine machine, thus ensuring very little downtime at a switchover from one production to another.

Cost-efficient Operation and Maintenance

It is an economical pump filling machine to operate. They are energy-saving machines and need more manpower than other filling techniques. In comparison to other types of filling machines, there are typically fewer mechanical moving parts with such equipment, and therefore, the maintenance requirements of these machines are relatively low. In turn, those fewer repairs and part changes than not only save money on total ownership structure.

Responsible and Safe Manufacturing

Pump filling machines are advantageous for companies dedicated to sustainability. They fill accurately - cutting down not only on material waste, but also on the use of non-biodegradable packaging materials - and they are designed and built for use with eco-friendly packaging. Safety is another key benefit because these machines offer a controlled setting that reduces spills and exposure to dangerous fluids.

Leveraging Advanced Filling Technology

Conclusion Joining a pump filling machine to your production line is an action that promises you a world of benefits in return. Its flexibility, adaptiveness, and accuracy are features that the industry cannot do without. When you select the appropriate pump filling machine, you will be able to improve your production capacity, keep quality standards high, minimize expenses, and promote sustainability. This investment, in turn, increases operational efficiency and sets your business up for growth and success in a competitive market.